What is the Kashiwazaki-Kariwa Nuclear Power Station?

The Kashiwazaki-Kariwa Nuclear Power Station stands as a testament to Japan's resilience and innovation in the energy sector.

0/0

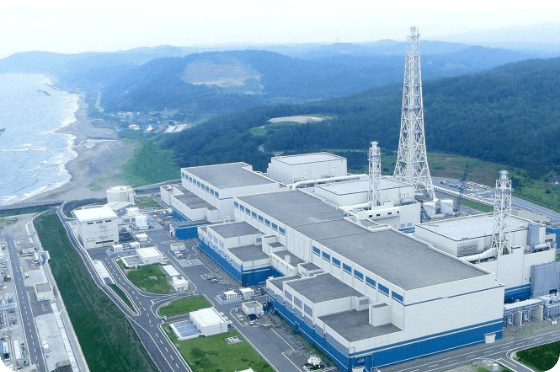

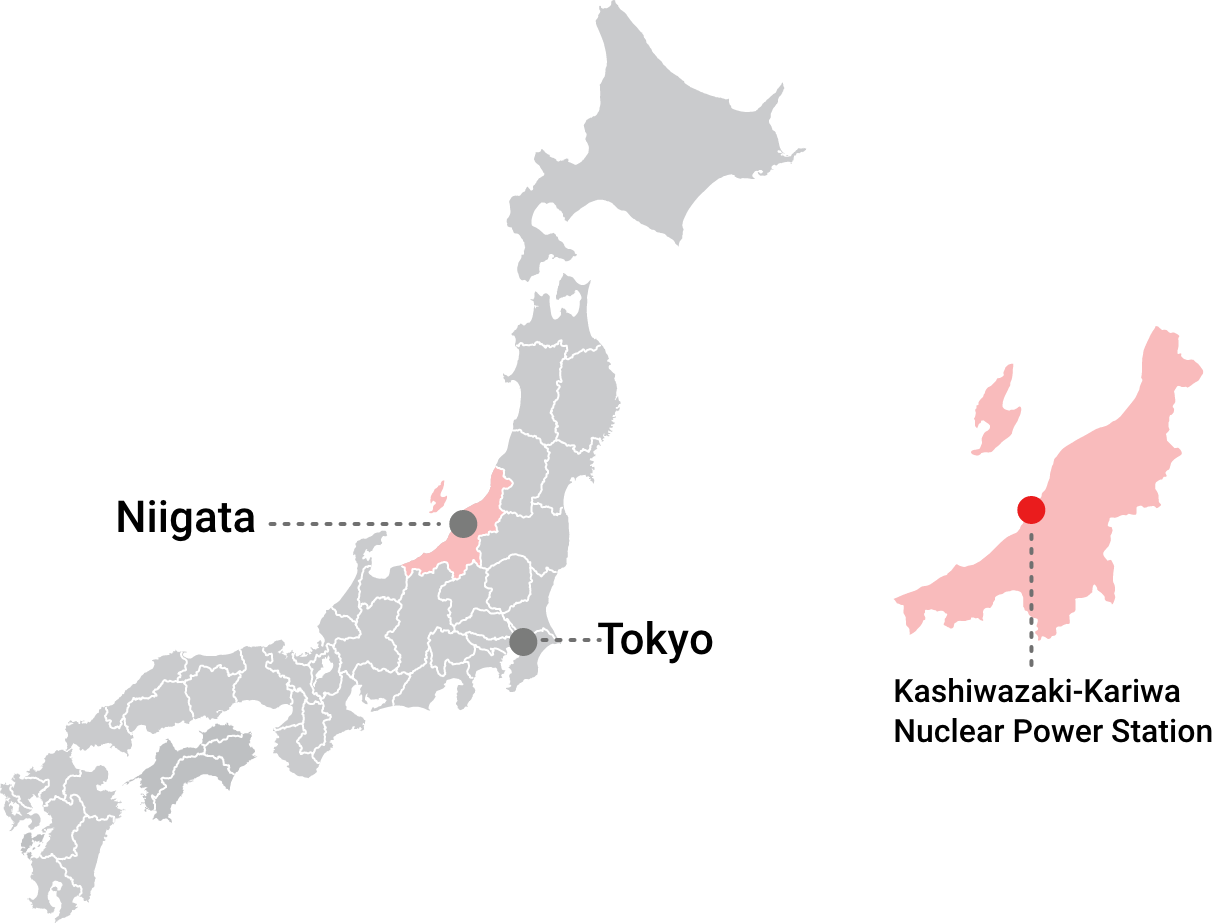

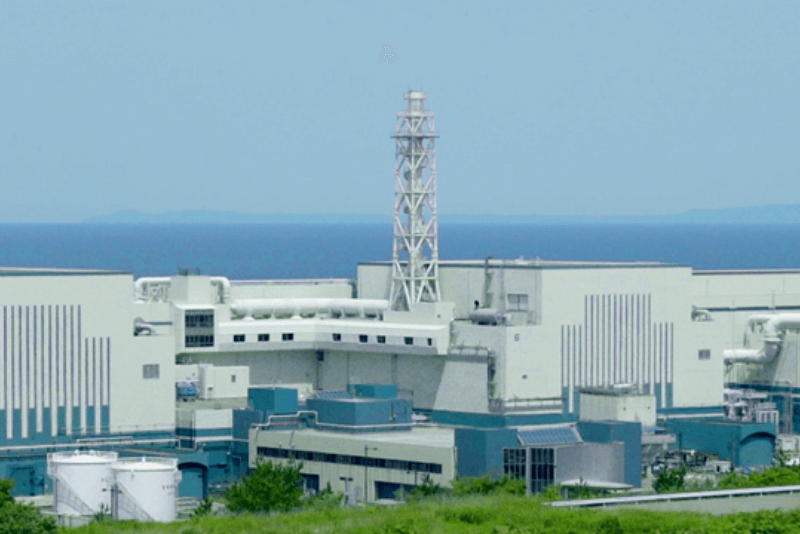

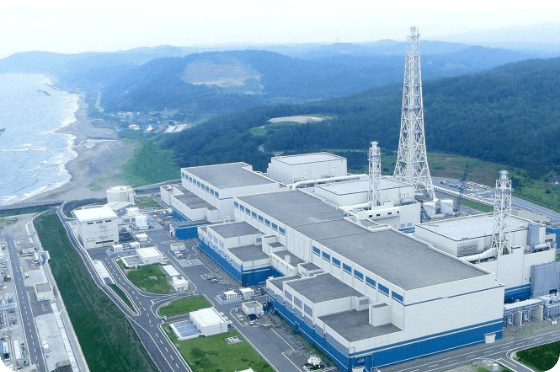

The Kashiwazaki-Kariwa Nuclear Power Station (KNPS) stands as a testament to Japan's resilience and innovation in the energy sector. Situated along the picturesque coastlines of Niigata Prefecture, on the western side of Japan's mainland Honshu, the station spans both Kashiwazaki City and Kariwa Village, facing the sea. With its advanced engineering and substantial capacity, KNPS plays a pivotal role in Japan's pursuit of energy security, economic stability, and decarbonization goals. This connection to the region's energy history dates back to the Nihon Shoki, where crude oil was offered to Emperor Tenji in 668. The development of the Nishi-Yama oil fields in the Meiji period and the subsequent construction of refineries in Kashiwazaki further solidified the area's role in energy production. Japan's transition from oil to nuclear energy began as the country sought to ensure a stable energy supply, aiming to reduce reliance on oil. Nuclear power, with its ability to provide large-scale, stable electricity generation, plays a key role in meeting Japan's future energy needs. It will continue to be essential in ensuring a reliable and decarbonized energy supply to support the country's growing demand. Construction of the KNPS began in 1978, with all units completed by 1997, representing decades of local development. Looking forward, it remains an integral part of Japan’s energy strategy, contributing to the nation's long-term goals of sustainability and energy security.

The Kashiwazaki-Kariwa Nuclear Power Station (KNPS) covers approximately 4.2 square kilometers (420 hectares) and is one of the largest nuclear power facilities in the world. With seven reactors and a total output of 8.212 gigawatts (GW), KNPS plays a critical role in Japan’s energy infrastructure, capable of powering millions of households.

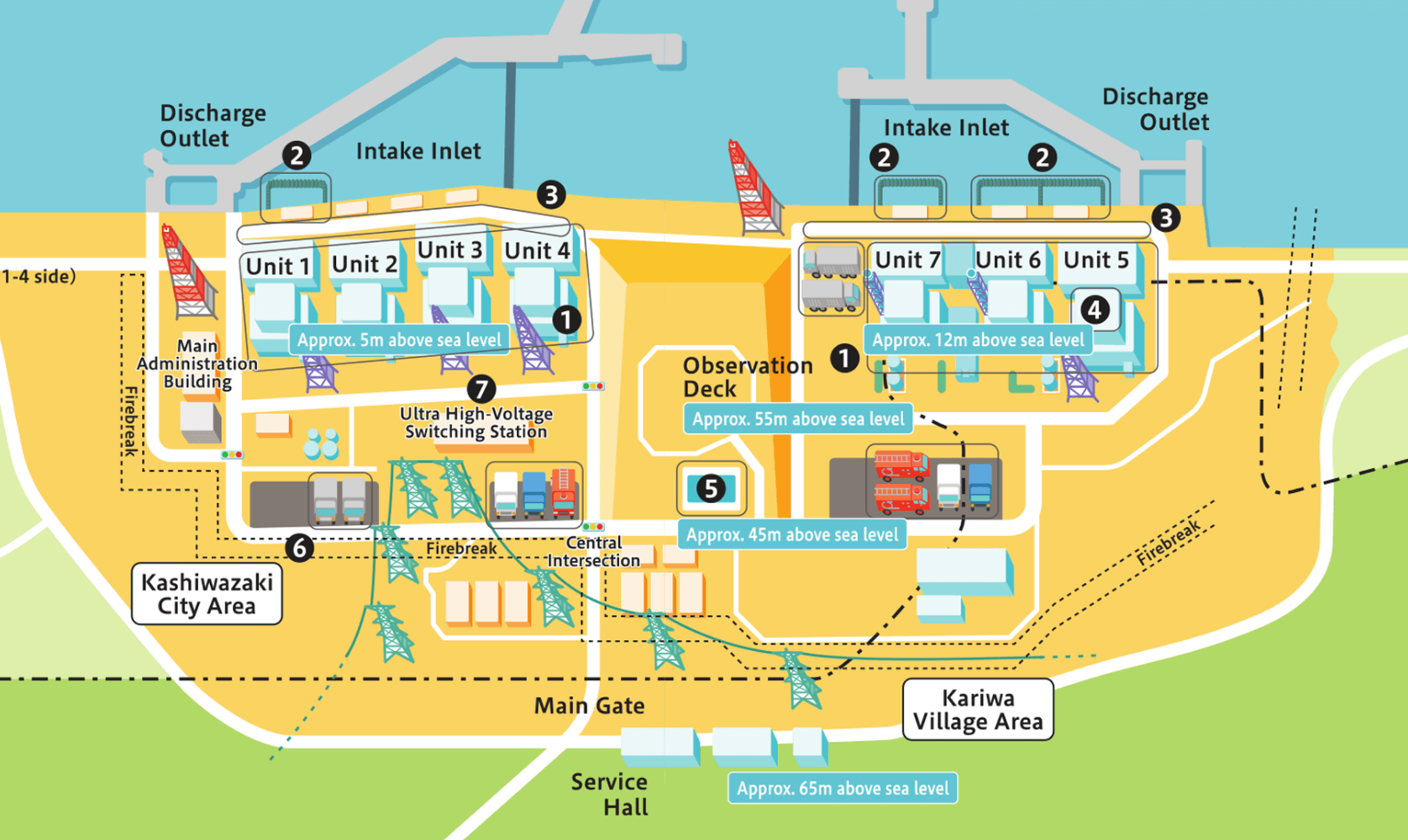

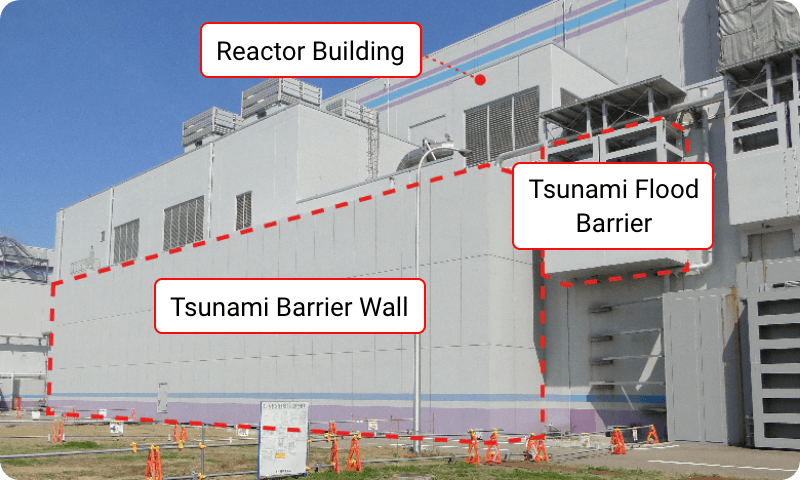

The facility is strategically designed to enhance both efficiency and safety, featuring a range of specialized infrastructure and defenses:

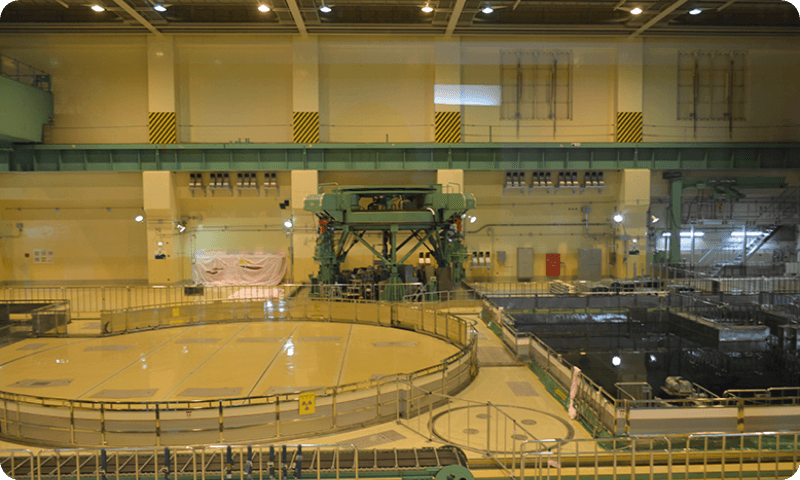

Each reactor is housed in a dedicated structure, and a separate a turbine building is used for electricity generation. Backup diesel generators are installed to ensure critical operations can continue in the event of a power loss.

To secure cooling water even in the event of a tsunami’s receding waters, KNPS has installed retaining weirs near intake points, ensuring continuous operation.

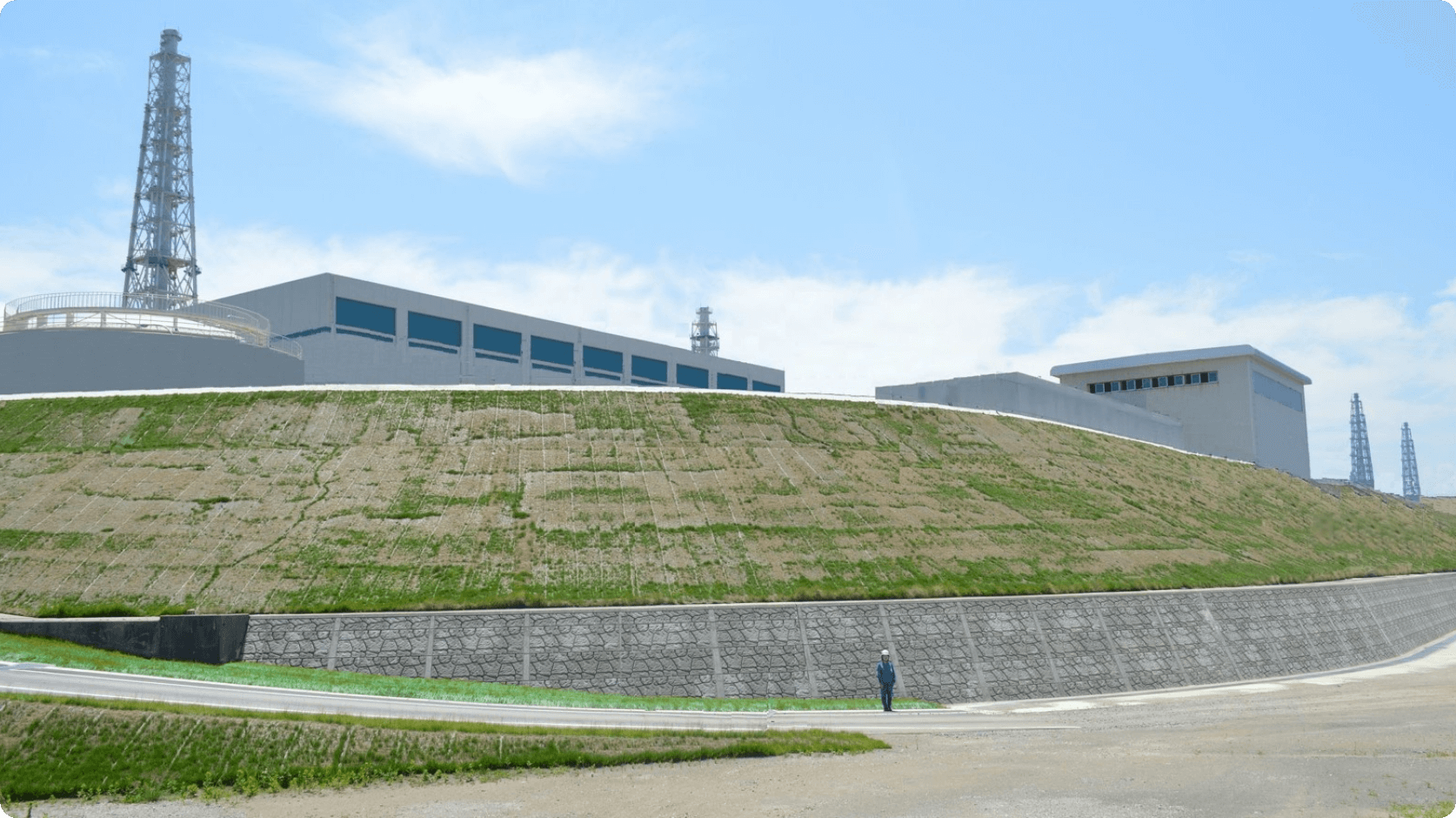

For the 7-8-meter-predicted-height of the largest tsunami that could impact the Kashiwazaki-Kariwa Nuclear Power Station, on the 5–7 reactor side, a 1-kilometer-long embankment combines a 3-meter-high cemented soil berm with the natural elevation of 12 meters above sea level for added protection. For the 1–4 reactor side, a 1.5-kilometer-long reinforced concrete seawall reaches 15 meters above sea level.

KNPS is equipped with a dedicated emergency response center to support central control rooms and manage crisis scenarios efficiently.

Positioned 45 meters above sea level, a freshwater reservoir with a capacity of approximately 20,000 tons provide an additional source of cooling water supplying the reactors and spent fuel pools for emergencies.

KNPS is equipped with firebreak zones—banded areas cleared of combustible materials—to prevent the spread of external fires to critical infrastructure.

Located at elevation point, this switching station facilitates the transfer of external power to the station, ensuring a stable power supply for plant operations and emergency systems.

Air-cooled gas turbine generator vehicles are distributed multiple places across high ground at 21 meters and 35 meters above sea level. These vehicles act as alternative power sources if transmission lines or emergency diesel generators are unavailable.

Hi-capacity water engines, fire trucks, alternative heat exchanger trucks, power supply vehicles are stationed at 35 meters above sea level or higher to ensure tsunami resistance and quick access to plant facilities.

| Unit 1 | Unit 2 | Unit 3 | Unit 4 | Unit 5 | Unit 6 | Unit 7 | |

|---|---|---|---|---|---|---|---|

| Status | Shutdown | Shutdown | Shutdown | Shutdown | Shutdown | Shutdown | Shutdown |

| Electric Output | 1.1 GW | 1.356 GW | |||||

| Construction Start | December 1978 | October 1983 | July 1987 |

February 1988 | October 1983 | September 1991 | February 1992 |

| Commercial Operation Start | September 1985 | September 1990 | August 1993 |

August 1994 |

April 1990 |

November 1996 | July 1997 |

| Reactor Type | Boiling Water Reactor (BWR) | Advanced Boiling Water Reactor (ABWR) | |||||

| Containment Type | Mark II | Improved Model Mark II | Reinforced Concrete Containment Vessel (RCCV) | ||||

| Localization Rate (%) | 99 | 89 | |||||

| Main Contractor | Toshiba | Hitachi | Toshiba / Hitachi / GE | ||||

| Reactor Thermal Output (GW) | 3.293 | 3.926 | |||||

| Number of Fuel Assemblies (Units) | 764 | 872 | |||||

| Fuel Assembly Length (m) | ~4.47 | ||||||

| Control Rods (number) | 185 | 205 | |||||

| Pressure Vessel Diameter (m) | 6.4 | 7.1 | |||||

| Pressure Vessel Total Height (m) | 23 | 21 | |||||

| Pressure Vessel Weight (t) | 750 | 910 | |||||

| Containment Vessel Height (m) | ~48 | ~36 | |||||

| Containment Vessel Diameter (m) | 26 | 29 | |||||

| Suppression Pool Water Volume (t) | 3,300 | 4,000 | 3,600 | ||||

| Turbine Speed (rpm) | 1,500 | ||||||

| Steam Inlet Temperature (°C) | 282 | 284 | 282 | 284 | 282 | 284 | |

| Steam Pressure (kg/cm²g) | 66.8 | 68.2 | |||||

| Fuel Type | Uranium Dioxide | ||||||

| Uranium Load (t) | 132 | 150 | |||||

| Fuel Assemblies (Units) | 764 | 872 | |||||

Restart Process Steps

*For more detailed information on restart process steps, please visit the website of Nuclear Regulation Authority.

The Fukushima Daiichi Nuclear Power Station Accident exposed critical weaknesses in nuclear safety, leading to significant global safety reforms. The key lessons learned were:

The failure of the sea wall emphasized the need for stronger tsunami protections.

The loss of power demonstrated the importance of backup power and cooling systems.

Since measures to prevent post-core damage hydrogen explosions and the release of radioactive substances were not sufficiently developed, multiple facilities are required to respond.

Delayed responses highlighted the need for better training, real-time monitoring, and improved communication.

In response, TEPCO adopted a defense-in-depth strategy, focusing on multiple safety barriers to protect against extreme events.

The Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has implemented advanced safety measures designed to mitigate risks from natural disasters, power loss, and reactor cooling. These measures, informed by lessons from the Fukushima Daiichi Nuclear Power Station Accident, are based on TEPCO’s "defense-in-depth" approach, ensuring safety through multiple layers of protection.

Seawalls and flood barrierssafeguard against tsunamis.

Earthquake-resistant reactor buildings, reinforced to exceed seismic standards.

Backup power systems and high-capacity batteries ensure uninterrupted power.

Independent power transmission lines provide secure external electricity.

A freshwater reservoir and mobile heat removal units

ensure effective reactor cooling, even in emergencies.

Filter vents manage risks associated with atmospheric radiation release.

Hydrogen treatment equipment in the reactor buildings does not run on electricity but rather uses catalysts to convert hydrogen and oxygen into steam, mitigating an increase in hydrogen concentration.

Regular training and emergency drills ensure staff readiness.

Emergency response plans and coordination with authorities safeguard public safety.

Superintendent Inagaki’s leadership, shaped by his direct experience during the Fukushima Daiichi Nuclear Power Station Accident, focuses on uncompromising safety. He emphasizes, "Because we have experienced such an accident, we will never compromise," and believes, "The pursuit of safety has no end."

Having led the recovery efforts at Fukushima, Inagaki reflects on the lessons learned, admitting, "I caused my subordinates to face extremely dangerous situations, and looking back, I am filled with profound regret. That memory weighs heavily on me, shaping my resolve to ensure such situations are never repeated." These experiences fuel his commitment to continuous improvement in safety.

Under his leadership, Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has strengthened safety measures, including multiple external power supplies, backup generators, and mobile units to ensure reliability during emergencies. Monthly emergency drills, including "blind drills" to test adaptability, and hands-on training, ensure staff readiness for any situation.

Inagaki fosters a culture of open communication, where everyone works toward a resilient, trusted power station. His vision for KNPS is a power station embraced by the local community, where all employees work with pride and vitality, aiming for greater heights.

In response to the Fukushima Daiichi Nuclear Power Station Accident, Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has placed even greater emphasis on transparent communication with local communities. Key initiatives include:

As Japan works to balance energy security, economic growth, and environmental sustainability, Kashiwazaki-Kariwa Nuclear Power Station (KNPS) is positioned to play a pivotal role in the country’s energy future. The increasing electricity demand driven by digital transformation (DX) and green transformation (GX) underscores the need for stable and reliable power sources. While renewable energy offers potential, its supply remains unstable, making nuclear power a key player in meeting the growing demand. KNPS, with its advanced infrastructure and significant capacity, is well-positioned to provide stable, low-carbon electricity to support both economic growth and environmental goals:

KNPS’s robust capacity will reduce Japan's reliance on fossil fuels and diversify the nation’s energy mix. By providing a stable, low-carbon energy source, it ensures reliable power generation, which is essential for Japan's economic stability and industrial growth.

KNPS contributes to Japan's commitment to reducing greenhouse gas emissions. By offering a low-carbon alternative to fossil fuels, the station plays a key role in helping Japan achieve its carbon neutrality targets by 2050.

Ongoing investments in technology, safety, and efficiency ensure KNPS’s long-term position as a cornerstone of Japan’s energy strategy. As AI and other DX technologies increase electricity demand, KNPS’s adaptability will allow it to meet these evolving needs while upholding environmental standards. KNPS’s focus on continuous improvement and innovation positions it to meet the challenges of a rapidly changing energy landscape.

KNPS is advancing in safety, sustainability, and community engagement with the goal of becoming a global example for large-scale energy operations. As Japan transitions towards a more sustainable energy future, KNPS will remain integral to balancing reliable energy with environmental responsibility.

The Kashiwazaki-Kariwa Nuclear Power Station stands as a testament to Japan's resilience and innovation in the energy sector.

The Fukushima Daiichi Nuclear Power Station Accident, while tragic, was a catalyst for TEPCO’s adoption of a defense-in-depth strategy, emphasizing a layered approach to nuclear safety.

By continuously evaluating and upgrading safety protocols, KNPS demonstrates its dedication to upholding the highest standards of nuclear safety, ensuring a safe and sustainable future.

Independent assessments by Japanese and international experts reaffirm TEPCO's commitment to transparency, accountability, and continuous improvement.

Contents