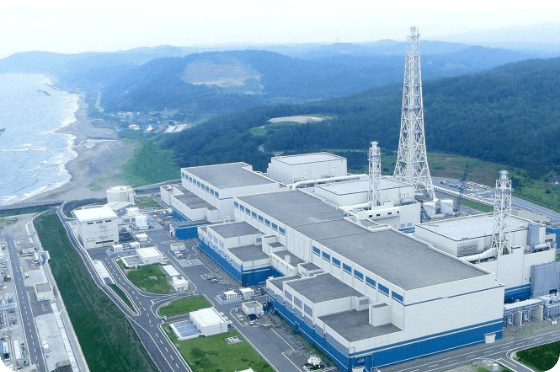

What is the Kashiwazaki-Kariwa Nuclear Power Station?

The Kashiwazaki-Kariwa Nuclear Power Station stands as a testament to Japan's resilience and innovation in the energy sector.

0/0

The Fukushima Daiichi Nuclear Power Station Accident exposed vulnerabilities in nuclear safety systems when faced with natural disasters. Located along the eastern coast of Japan's Honshu Island, near the Pacific Ocean, the incident served as a wake-up call worldwide, underscoring the need for improvements in both the design and operation of nuclear facilities. In response, new regulatory requirements were established, marking a significant step forward in the safe and sustainable use of nuclear energy.

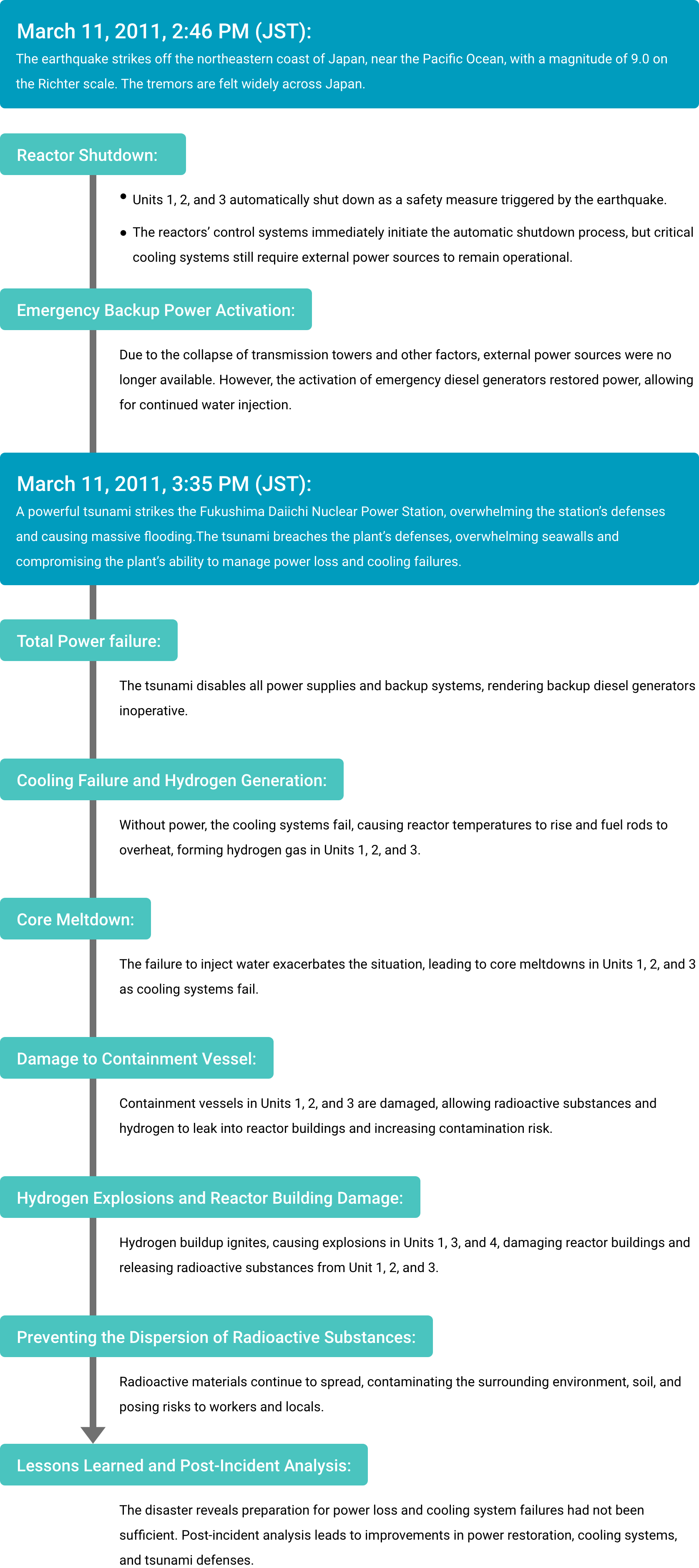

The Fukushima Daiichi Nuclear Power Station Accident, one of the largest nuclear disasters in history, was triggered by the catastrophic effects of a massive earthquake and subsequent tsunami on March 11, 2011. This timeline provides an overview of the key events immediately following the disaster, detailing the sequence of events and lessons learned.

The Fukushima Daiichi Nuclear Power Station Accident exposed vulnerabilities in nuclear station infrastructure and emergency protocols, as well as measures that were not sufficiently developed to enhance safety awareness at an organizational level. In response, TEPCO adopted a comprehensive "defense-in-depth" strategy, aimed at strengthening safety at multiple levels. This strategy is designed to prepare stations for a wide range of risks by introducing multiple safety barriers, which ensure that facilities are better equipped to handle extreme events and reduce the impact of accidents. These efforts have led to significant improvements not only in technical infrastructure but also in operational readiness and cultural shifts within TEPCO.

The failure of the seawall during the tsunami revealed serious weaknesses in the plant's flood protection systems. In response, TEPCO has prioritized the construction of higher seawalls and more robust flood barriers to protect against future tsunamis. Furthermore, critical equipment has been relocated above tsunami levels, ensuring that essential systems remain functional even during more powerful tsunamis than initially anticipated.

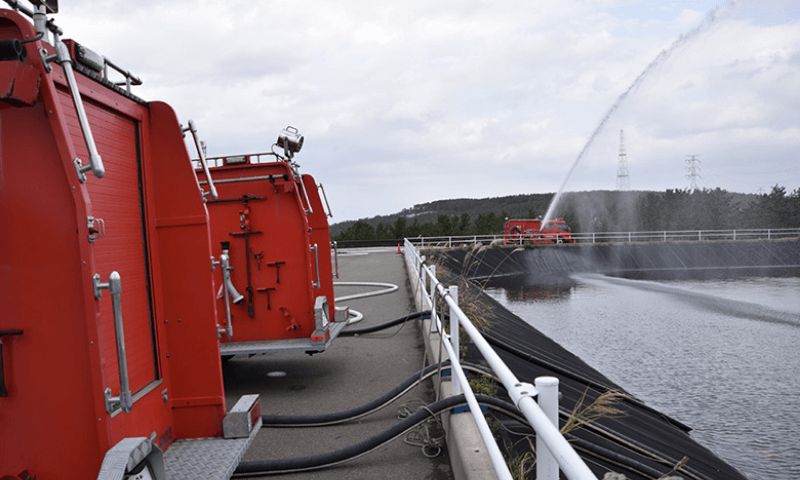

The loss of power caused by the tsunami highlighted the need for more reliable backup systems. As a result, modern stations now feature multiple redundant, mobile, and portable power sources, including diesel generators and battery banks. In addition, power supply vehicles are stationed on high ground to remain unaffected by tsunamis, ensuring continuous operation. The ability to inject coolant into the reactors using AC power sources, such as gas turbine generator trucks, for extended periods has been greatly enhanced, ensuring that cooling can be maintained even in challenging situations.

Hydrogen buildup in the reactors and reactor buildings led to explosions during the Fukushima Daiichi Nuclear Power Station Accident. To mitigate this risk, TEPCO has implemented advanced systems. These systems include recombiners designed for controlling hydrogen concentration and filter vents for preventing dispersion of radioactive substances. Together, these measures inhibit excessive hydrogen accumulation, hydrogen explosion and the spread of radioactive substances.

TEPCO has overhauled its crisis communication protocols to ensure more effective coordination during emergencies. Enhanced communication channels facilitate information sharing with local communities, the government, and other stakeholders. This enhances transparency and ensures rapid dissemination of critical information, helping to manage the crisis more efficiently and maintain public confidence.

Critical emergency equipment, including alternative heat exchanger trucks, power supply vehicles, and fire trucks, is now stationed on high ground to remain functional even in the event of a tsunami. The ability to deploy this equipment quickly has also been streamlined, enabling faster responses in emergencies. This preparedness ensures that resources can be mobilized without delay, even when the plant’s regular operations are disrupted.

TEPCO has improved its ability to respond to multiple simultaneous accidents by reinforcing infrastructure and increasing the stock of emergency equipment. Drills have been expanded to simulate a wide range of disaster scenarios, including total power loss and simultaneous failures at multiple plants. These exercises ensure that the organization is prepared for a variety of extreme events, making the response more coordinated and effective.

The Fukushima Daiichi Nuclear Power Station Accident underscored the need for significant cultural and operational shifts within the nuclear industry. In response, we have made a strong commitment to safety and transparency, driving continuous improvements across our operations. Some of the key changes include:

A major cultural shift has taken place within organizations, focusing on empowering workers at all levels. This shift encourages stronger collaboration among operators, regulators, and safety organizations. By fostering a more inclusive culture, the industry has enhanced safety awareness and decision-making processes, which are critical during crises.

Improvements in crisis communication protocols have been implemented, including the introduction of real-time updates and transparent information sharing. These measures are designed to build trust with both the public and local communities, ensuring that nuclear operations are understood, and that trust is maintained, even during emergencies.

As part of the defense-in-depth strategy, a comprehensive approach has been adopted to ensure robust operational preparedness at every stage of an emergency. This includes better preparedness for simultaneous multi-plant disasters, the reinforcement of safety systems, and the provision of advanced equipment for post-accident scenarios. This equipment includes radiation measurement tools and advanced communication systems, which ensure that TEPCO can effectively respond to and manage accidents when they occur.

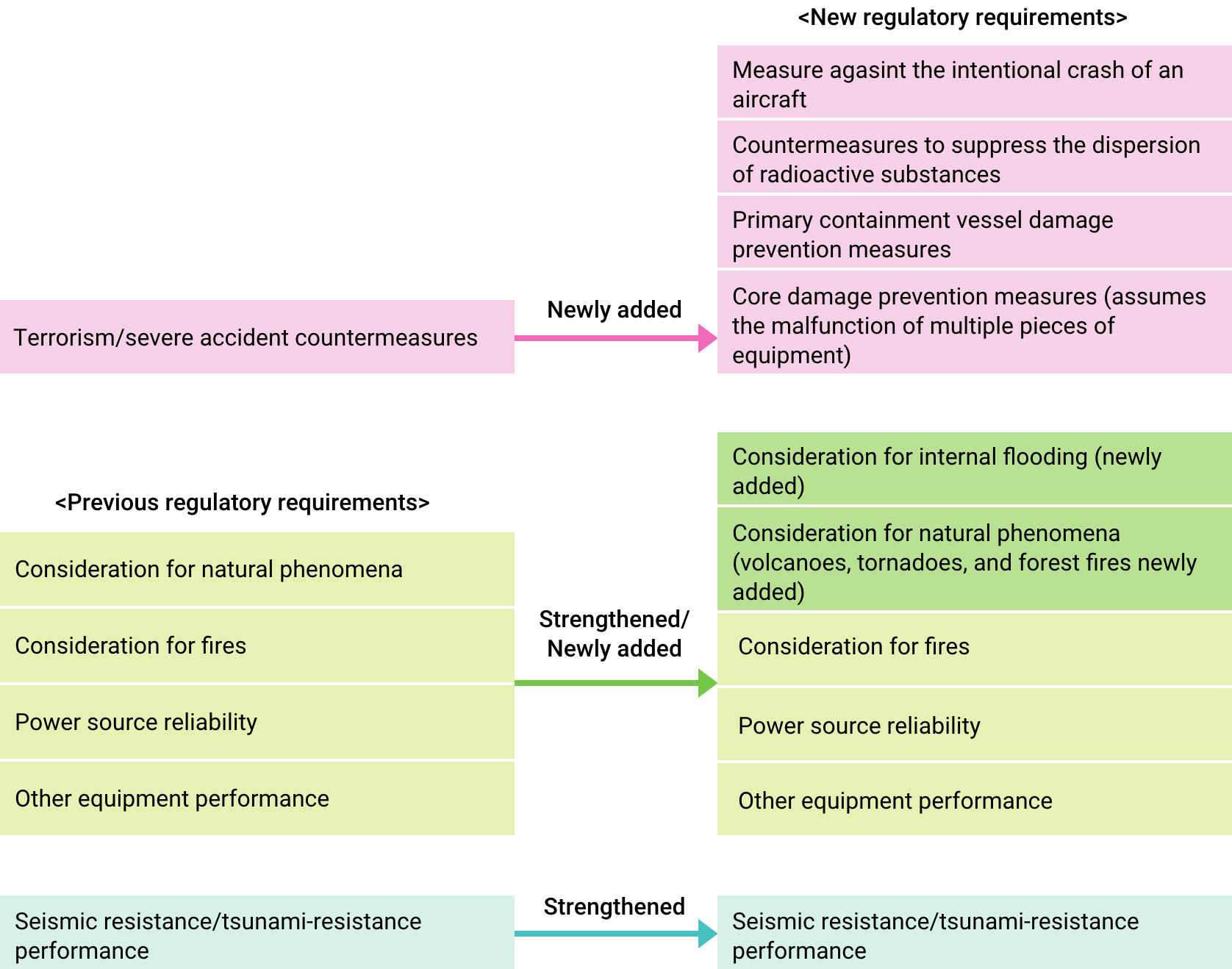

In July 2013, new regulatory requirements were introduced to significantly enhance safety across the nuclear industry. These requirements strengthened existing guidelines for natural phenomena such as earthquakes, tsunamis, volcanoes, and forest fires. Measures that were previously voluntary, like severe accident countermeasures and terrorism countermeasures, were also made mandatory.

To address potential threats, TEPCO has been developing procedures and mobile equipment to maintain safety during scenarios like power or water injection failures caused by intentional impacts, such as aircraft collisions. Regular drills are conducted to ensure readiness, and the government has implemented defense and diplomatic measures to address risks like missile strikes and military attacks.

Security measures have also been reinforced. TEPCO joint training exercises with police and the Japan Coast Guard are conducted regularly, alongside ongoing efforts to prevent unauthorized intrusions. Additionally, external experts, such as former police and fire officials, have been recruited to improve response capabilities.

Other system improvements include strengthened fire prevention measures, improved equipment reliability, and new guidelines to address internal flooding. Together, these advancements represent a comprehensive approach to ensuring greater safety and resilience in the nuclear sector.

The "defense-in-depth" philosophy is integral to nuclear station safety. It involves preparing countermeasures across various stages, from preventing accidents to mitigating the impact of core damage and beyond:

The first layer of defense focuses on preventing accidents, such as reinforcing tsunami defenses and sealing buildings to prevent flooding. For instance, flood barriers and watertight buildings are now standard, designed to withstand more powerful tsunamis than initially anticipated.

If a problem arises, the second layer aims to prevent it from escalating into a full-scale accident. Redundant systems such as additional power sources, manual reactor cooling systems, and increased battery capacity are deployed to maintain safety even under extreme conditions.

The third layer of defense ensures that if an accident occurs, the core is protected. This includes mechanisms to inject coolant into the reactor, lower pressure within the vessel, and remove heat through mobile heat exchangers and other systems designed to withstand adverse conditions.

The final layer aims to mitigate the impact if core damage occurs. This includes systems to cool primary containment vessels, reduce radioactive substances leakage through venting systems with filters, and minimize secondary disasters such as hydrogen explosions.

The Fukushima Daiichi Nuclear Power Station Accident, while tragic, was a catalyst for TEPCO’s adoption of a defense-in-depth strategy, emphasizing a layered approach to nuclear safety. The improvements made by the wider nuclear sector's response, reflect a broader effort to address the challenges faced by the industry. While significant progress has been made, the nuclear industry faces ongoing challenges, and it must continue evolving. The future of nuclear energy lies not only in improving safety measures but also in fostering international collaboration, sharing best practices, and ensuring the sector's resilience in the face of future challenges. By continuously improving infrastructure, emergency response systems, and organizational culture, the nuclear industry is working towards a safer, more reliable energy future for the global community.

The Kashiwazaki-Kariwa Nuclear Power Station stands as a testament to Japan's resilience and innovation in the energy sector.

The Fukushima Daiichi Nuclear Power Station Accident, while tragic, was a catalyst for TEPCO’s adoption of a defense-in-depth strategy, emphasizing a layered approach to nuclear safety.

By continuously evaluating and upgrading safety protocols, KNPS demonstrates its dedication to upholding the highest standards of nuclear safety, ensuring a safe and sustainable future.

Independent assessments by Japanese and international experts reaffirm TEPCO's commitment to transparency, accountability, and continuous improvement.

Contents