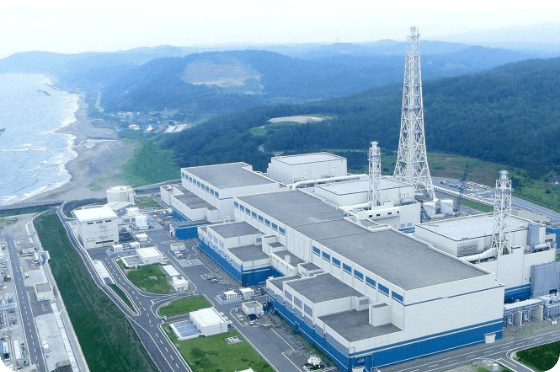

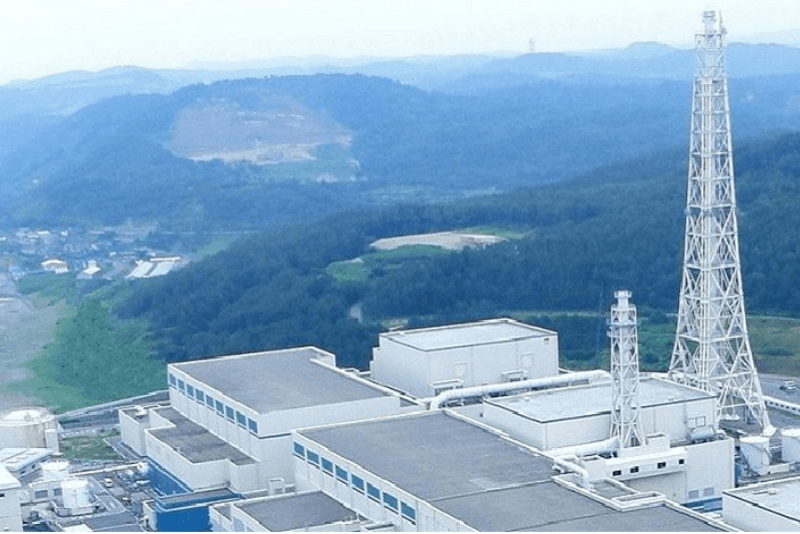

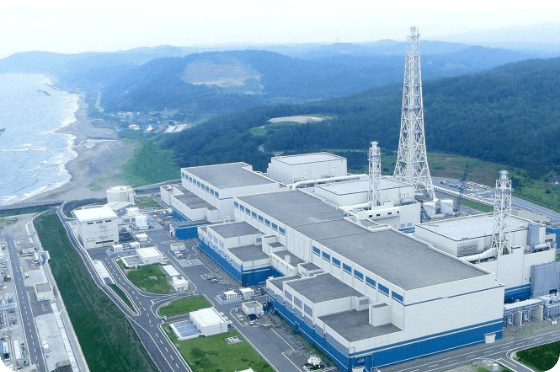

What is the Kashiwazaki-Kariwa Nuclear Power Station?

The Kashiwazaki-Kariwa Nuclear Power Station stands as a testament to Japan's resilience and innovation in the energy sector.

0/0

Drawing from the lessons of the Fukushima Daiichi Nuclear Power Station Accident, the Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has implemented extensive multi-layered safety measures. These enhancements are designed to mitigate risks associated with earthquakes, tsunamis, power loss, reactor cooling, and radioactive substances management. This commitment to safety is grounded in the principle of "defense-in-depth," where TEPCO prioritizes safety above all else, and operations will be halted immediately if any issues arise. By applying the lessons learned from the Fukushima Daiichi Nuclear Power Station Accident, TEPCO is ensuring the highest safety standards.

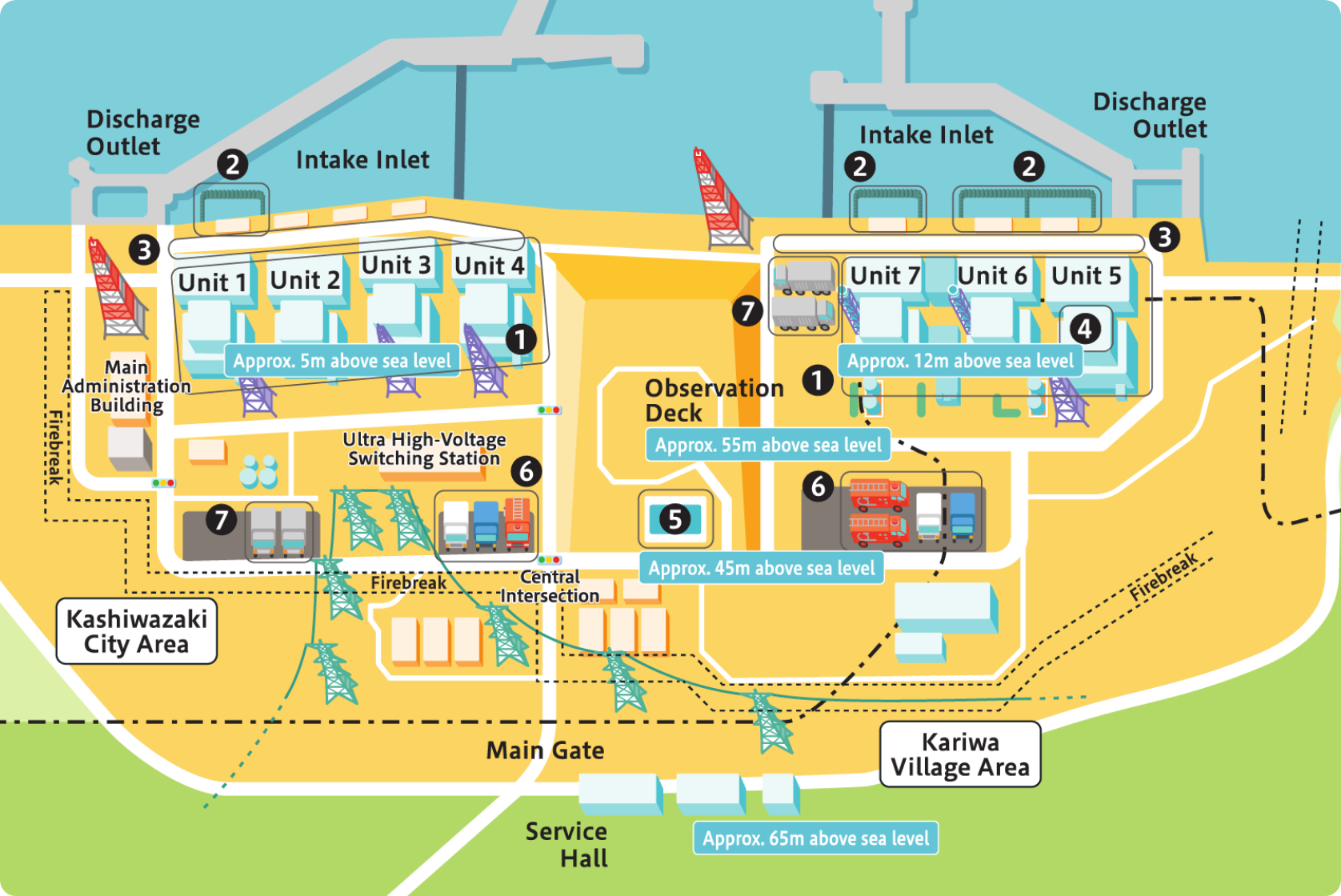

Click a number on the map to see detailed information about each measure.

Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has fortified its infrastructure with robust measures against natural disasters, particularly earthquakes and tsunamis, drawing lessons from the Fukushima Daiichi Nuclear Power Station Accident. The following safety initiatives have been put in place:

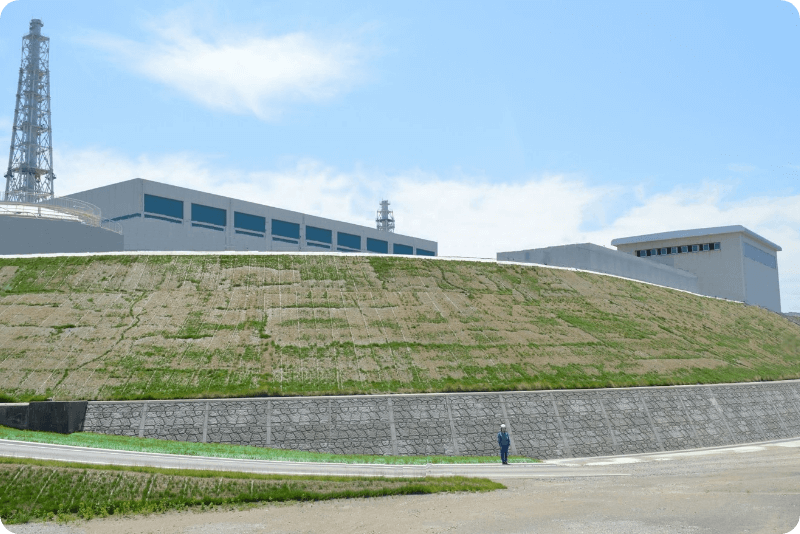

In response to the 2011 Tōhoku earthquake and tsunami, KNPS has developed several strategies to prevent damage from tsunamis:

The plant is protected by seawalls and flood barriers designed to withstand tsunamis up to 15 meters high, significantly exceeding the predicted height of the largest tsunami expected to impact the area, which simulations estimate at 7-8 meters. The seawall, reinforced with cement-treated soil and built to endure seismic activity, extends approximately 1,000 meters to prevent seawater from flooding the station. Additionally, flood barriers and watertight doors have been installed to safeguard critical areas, ensuring comprehensive protection against potential tsunami impacts.

▲MAPTo address seismic threats, particularly in Japan’s seismically active region, KNPS has strengthened its infrastructure:

The reactor buildings are anchored to stable bedrock, reducing seismic risk.

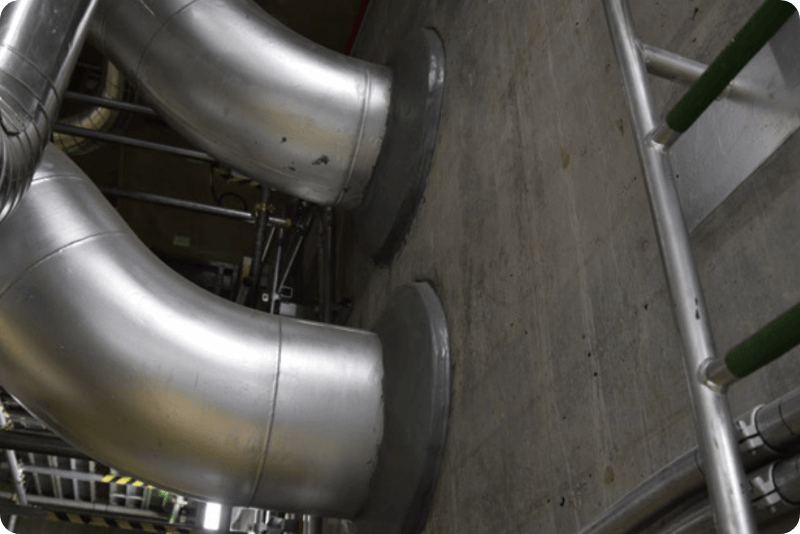

After the 2007 Niigata Chuetsu-Oki Earthquake, the plant underwent significant reinforcements, including strengthening pipe supports and roofs to enhance earthquake resistance.

To meet the new regulatory requirements issued after the Fukushima Daiichi Nuclear Power Station Accident, 1,400 to 3,000 additional pipe and conduit supports were installed per reactor unit, alongside reinforced roof trusses.

▲MAPKNPS has implemented several emergency systems to ensure safety during earthquakes or tsunamis:

The plant includes multiple levels of protection, regularly evaluated to handle worst-case scenarios such as simultaneous earthquakes and tsunamis.

▲MAPTo ensure uninterrupted operations during emergencies, Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has implemented significant power system upgrades focused on redundancy, reliability, and quick recovery.

Emergency diesel generators, power supply vehicles, and air-cooled gas turbine generator trucks are strategically located in areas unaffected by tsunamis to ensure no single point of failure disrupts critical systems.

Diesel generators are located in flood-free zones, while power supply vehicles are ready for rapid deployment to maintain power to essential systems during emergencies.

Two GTGs, capable of generating substantial power, are stationed in both of Unit 1-4 side and around Unit 7 at high-ground areas, ensuring backup power during system failures.

▲MAPThe plant is connected to five transmission lines routed through three independent paths, providing redundancy in case of damage to any line and ensuring a continuous power supply for critical operations

If external power is lost, backup systems automatically activate to maintain essential functions, such as reactor cooling and safe shutdown.

▲MAPIn addition to the original batteries installed during construction, additional high-capacity batteries have been placed at elevated locations. These batteries provide reliable power to monitoring and control systems during emergencies, unaffected by flooding.

Additional DC power sources at elevated locations ensure stability in critical control systems, such as reactor cooling and safety monitoring, even if the main power supply is compromised.

▲MAPIn case of a station blackout (total loss of external power), power supply vehicles and GTGs can be rapidly deployed from tsunami-safe locations within the plant site, ensuring a swift and reliable restoration of power.

A freshwater reservoir, positioned 45 meters above sea level, stores 20,000 tons of water for reactor and spent fuel pool cooling. Alternative heat exchanger trucks on high ground ensure cooling continues with using seawater even if primary systems are flooded.

▲MAPEffective cooling is essential for maintaining the safety of the reactors under any scenario. In the case of a malfunction or failure in the primary systems, multiple backup measures are in place to ensure the continued safe operation of the reactors and prevent overheating.

A reservoir, situated 45 meters above sea level, is designed to hold approximately 20,000 tons of freshwater. This reserve ensures an uninterrupted supply of cooling water for at least 7 days, even if all primary systems fail.

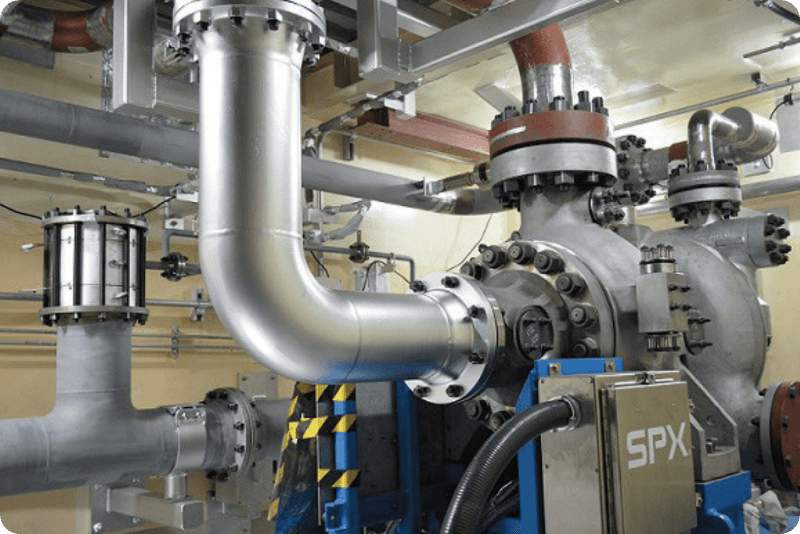

To maintain reactor cooling, multiple water injection systems, including mobile units, can be activated. These include both electric-powered pumps and steam-driven pumps such as Emergency core cooling system (ECCS) and High-pressure alternate cooling system (HPAC), which ensure continued water supply to the reactors and spent fuel pools in case of a complete loss of power. The placement of fire trucks and the freshwater reservoir throughout the site also ensures that no single failure can disable all cooling functions simultaneously.

▲MAPThese mobile units provide crucial cooling capabilities in case of severe flooding or failure of primary cooling systems. These systems are designed to prevent the release of radioactive substances by ensuring cooling even under extreme conditions.

The reactor building is equipped with various methods for heat removal, including connections to alternative heat exchangers using seawater and backup electrical power sources. These systems ensure the reactor can be cooled for a prolonged period of about 10 days, even in the event of primary cooling system failure.

▲MAPA robust set of systems has been implemented to prevent hydrogen buildup and the potential spread of radioactive substances during emergency scenarios.

Installed on the upper levels of the reactor building, this system utilizes catalytic recombination to convert hydrogen into water, preventing the buildup of hydrogen and the risk of explosions.

▲MAPThis system vents gases from the containment vessel during emergencies, removing 99.9% of particulate radioactive materials and inorganic iodine, and 98% of organic iodine, reducing the risk of atmospheric radiation release.

▲MAPTo ensure that all potential emergency scenarios are managed effectively, Kashiwazaki-Kariwa Nuclear Power Station (KNPS) has established comprehensive emergency protocols and conducts regular drills to maintain readiness.

Detailed evacuation plans and communication systems are in place to guarantee that both the public and employees are informed and safe in the event of an emergency.

KNPS coordinates closely with local and national authorities to ensure a unified and effective emergency response.

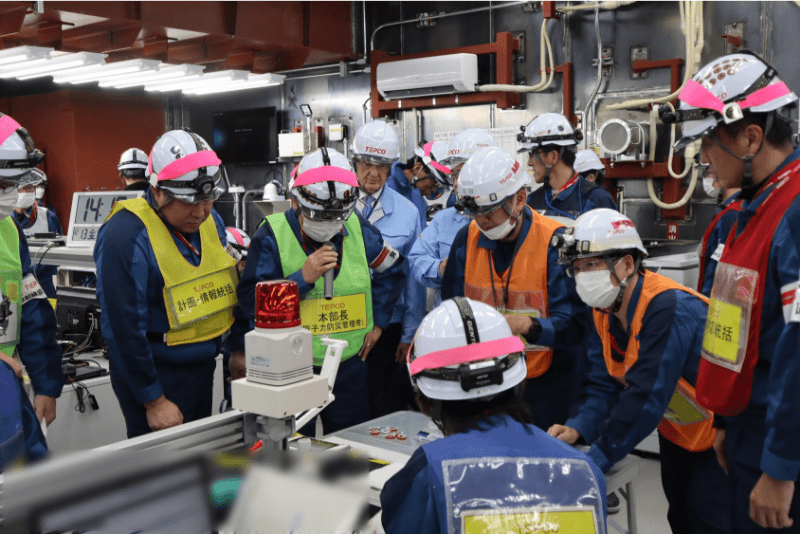

▲MAPKNPS regularly conducts not only general emergency exercises but also individual emergency response drills such as simulator trainings, power supply drills, and connection drills for cooling water injection for its staff, enhancing their ability to respond to different types of crises.

These drills simulate a variety of potential disasters, from natural events such as tsunamis and earthquakes to accidents within the plant, ensuring that the team is well-prepared for any situation.

As part of its emergency preparedness, KNPS regularly carries out blind exercises. In these exercises, the scenario is not disclosed beforehand, helping the team develop a quick and effective response to unforeseen events. This approach strengthens their ability to remain adaptable and make sound decisions in high-pressure situations.

▲MAPEffective management of radioactive substances is crucial for ensuring safety both during normal operations and in the event of an emergency.

The storage and handling of radioactive materials are conducted with state-of-the-art systems that prevent any leaks or spills.

Radiation levels are constantly monitored using advanced detection equipment, which allows for rapid identification and mitigation of potential risks.

KNPS’s monitoring systems ensure that all data is continuously updated and available, allowing for immediate corrective action if needed.

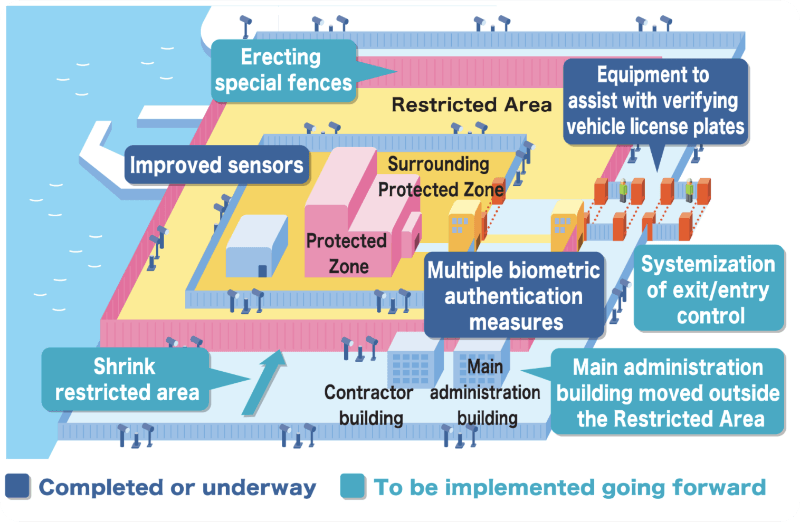

▲MAPTo further enhance the safety of the facility, security measures have been updated to prevent unauthorized access and to better protect nuclear materials. Improved monitoring systems ensure that both personnel and materials are properly safeguarded, with ongoing efforts to raise security standards at the plant.

The Kashiwazaki-Kariwa Nuclear Power Station (KNPS) employs state-of-the-art safety measures informed by past experiences and rigorous testing. These measures reflect a commitment to ensuring operational safety and protecting surrounding communities against natural disasters and unforeseen events. The summary of these safety measures showcases TEPCO’s "defense-in-depth" approach, which prioritizes safety above all else. By continuously evaluating and upgrading safety protocols, KNPS demonstrates its dedication to upholding the highest standards of nuclear safety, ensuring a safe and sustainable future.

The Kashiwazaki-Kariwa Nuclear Power Station stands as a testament to Japan's resilience and innovation in the energy sector.

The Fukushima Daiichi Nuclear Power Station Accident, while tragic, was a catalyst for TEPCO’s adoption of a defense-in-depth strategy, emphasizing a layered approach to nuclear safety.

By continuously evaluating and upgrading safety protocols, KNPS demonstrates its dedication to upholding the highest standards of nuclear safety, ensuring a safe and sustainable future.

Independent assessments by Japanese and international experts reaffirm TEPCO's commitment to transparency, accountability, and continuous improvement.

Contents