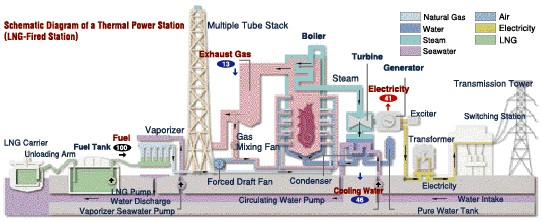

1. Steam power generation (LNG-Fired Station)

Steam power plant facilities constitute a means of power generation that uses the expansion power of steam. Fuel is burned inside a boiler to heat water and generate steam. This steam is then used to drive turbines which in turn drive the power generators to make electricity. This steam is suitable for the use of thermal energy of relative low temperature (below 600°C).

Fuel Tanks

Natural gas produced in such places as Malaysia, Brunei, Das Island, and Alaska is converted onsite to liquefied natural gas (LNG) with a temperature of -162°C and a volume that is 1/600th of the original gas, and transported in specially designed vessels. After the LNG has been stored in tanks with a double-walled construction like that used for a thermos flask, it is turned back into gas by a vaporizer and transferred to the boiler. One kilogram of LNG generates heat equivalent to some 13,000 kcal.

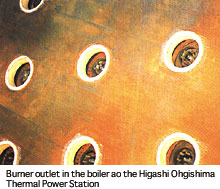

Boilers

Boilers burn the fuel transferred from the tank and use the resulting heat to convert water into steam. Inside the boilers are tens of thousands of water-carrying tubes. When combustion commences, the temperature inside the boilers rises to between 1,100 and 1,500°C, the water inside the tubes is turned into high-temperature and high-pressure steam, and the steam is transferred to the steam turbines.

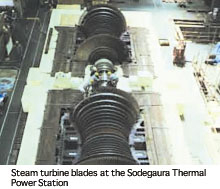

Turbines

The steam rotates the turbine blades at a high speed of 3,000 rpm. This turns the power generator, which is directly connected to the turbines, and electricity is produced as a result. This electric power is then delivered along power transmission lines and through substations to the homes of customers. The steam is cooled by seawater in a condenser, restored to water, and then returned to the boiler for reuse. This cycle of water to steam to water is repeated over and over again.

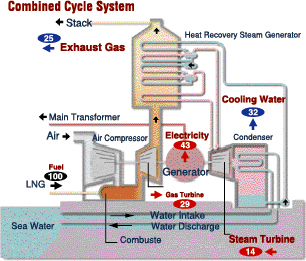

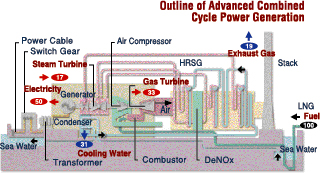

Combined cycle power generation is a method of generating electric power that combines gas turbine power generation with steam turbine power generation. By employing a 1,100°C class gas turbine in the high-temperature section and by effectively recycling the exhaust energy of this section in the steam system, the thermal efficiency can be boosted to 43%. Furthermore, several small-capacity individual units are combined to configure a large-capacity power generation facility, and startup and shutdown operations can be easily tailored to the fluctuation in demand.

TEPCO turned its attention to the above-mentioned benefits of combined cycle power generation at the early date of 1986 and introduced it to the Futtsu Thermal Power Station, where a combined total of 2,000 MW are generated by Group1 and Group 2.

With advanced combined cycle (ACC) power generation, the inlet gas temperature of the gas turbine is raised to 1,300°C, higher temperature and pressure levels are established as in the steam conditions in the steam turbines, and a reheating cycle is also employed to improve the thermal efficiency. These enhancements increase the thermal efficiency of ACC power generation to 50%.

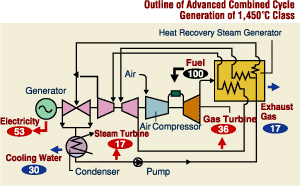

This system is based on the ACC power generation system and achieves even higher efficiency and capacity by raising the inlet gas temperature of the gas turbine to even higher levels. By raising the temperature to 1,450°C through such technical innovations as the development of heat-resistant materials for the gas turbines and gas turbine steam cooling, the thermal efficiency has been improved to 53%.

Future plans call for TEPCO to introduce the 1,450°C class of combined cycle power generation to its Kawasaki Thermal Power Station and Futtsu Thermal Power Station Group 4.

© Tokyo Electric Power Company Holdings, Inc.