Since August 24, 2023, we have commenced the discharge of ALPS treated water into the sea. This water was stored in tanks, and confirmed prior the discharge that the concentrations of radioactive substances, excluding tritium, meet the government’s regulatory standards after the purification by multi-nuclide removal equipment (ALPS), etc.

Therefore, the amount of water being stored in these tanks will gradually decrease over time.

See the Treated Water Portal Site for information on the future handling of treated water*.

Note on “Water treated with multi-nuclide removal equipment, etc. (ALPS treated water)” is notated.

"ALPS treated water" refers to water that has been purified with multi-nuclide removal equipment (ALPS), etc. until the concentrations of radioactive substances, excluding tritium, meet the government’s regulatory standards (The sum of the ratio of legally required concentrations, excluding tritium, being less than 1).

Water that has been purified with multi-nuclide removal equipment (ALPS), etc., but has yet to fulfill the government’s regulatory standards (The sum of the ratio of legally required concentrations, excluding tritium, being 1 or higher) is referred to as, "treated water to be re-purified". When referring to both of the aforementioned types of treated water collectively, "ALPS treated water, etc." is used.

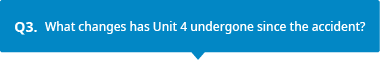

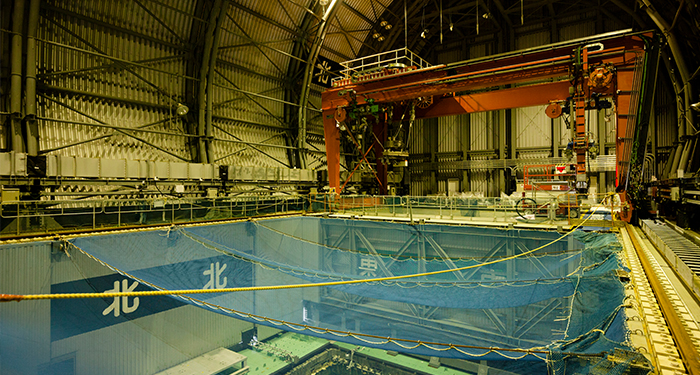

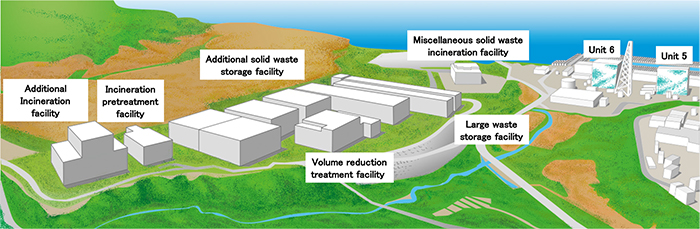

Drag the screen for a 360° view.

Drag the screen for a 360° view.