Each TEPCO Group company abides by its own environmental management system* to ensure compliance with environmental laws and regulations, prevent pollution, steadily improve environmental performance, and otherwise manage the environmental aspects of its diverse business activities, and strives to improve the system on an ongoing basis.

* Environmental Management System (EMS)

A management scheme that promotes and controls the voluntary and ongoing efforts of companies and organizations to address environmental issues.

The CSR Committee Environmental Management Panel established in the TEPCO Head Office sets environmental policies and targets for the entire Group, promotes environmental measures, and checks and reviews environmental performance. In other offices, the Environmental Committee assumes that role.

The TEPCO Advisory Committee on Environmental Affairs, composed of outside experts and specialists, provides guidance and advice on improving TEPCO's environmental initiatives. (See pp. 76-77 for details.)

Additionally, TEPCO and 40 Group companies have established the Group Environmental Committee to improve the Group's environmental management by sharing information, reducing environmental risks, and publicly disclosing pertinent information, as its priority policies.

Environmental management framework

* Offices: Branch offices, power system offices, thermal power offices, nuclear power stations, construction offices

* Offices: Branch offices, power system offices, thermal power offices, nuclear power stations, construction offices

All TEPCO offices that implement environmental conservation activities, including branch offices and power stations, establish and operate an environmental management system (EMS) conforming to the ISO14001* standard.

An Environmental Audit Team composed of employees from each business unit regularly performs an internal environmental audit to verify EMS implementation status, and applies the audit results to improving daily operations and reviewing various systems to ensure continuous EMS enhancement.

TEPCO also considers ISO14001 certification as an effective tool for receiving objective third-party assessments of EMS operations and for taking environmental management to a higher level. Some TEPCO offices that have already acquired ISO14001 certification are actively improving their EMS based on the certification.

* ISO14001

An international standard for environmental management systems established by the International Organization for Standardization.

ISO14001 certification status

| Office | Scope of registration | Registration |

| Yamanashi Branch Office | All offices under its management | December 27, 1999 |

|---|---|---|

| Chiba Branch Office*1 | All offices under its management | March 29, 2000 |

| Kashiwazaki-Kariwa Nuclear Power Station | Entire site of the Kashiwazaki-Kariwa Nuclear Power Station | August 20, 2001 |

| Higashi Thermal PowerOffice*2 | Head office and all thermal power stations under its operation (the Chiba, Goi, Anegasaki,Sodegaura, and Futtsu Thermal Power Stations) | February 25, 2002 |

| Nishi Thermal PowerOffice*3 | Head office and all thermal power stations under its operation (the Minami-Yokohama, Higashi-Ohgishima, Yokohama, Kawasaki, and Yokosuka Thermal Power Stations) | March 25, 2003 |

Tokyo Electric Power Services Co., Ltd., a member of the TEPCO Group, provides advice and tools to support the establishment and operational improvement of EMS in other Group companies through the Group Environmental Committee. It also provides basic EMS training and company-specific internal environmental audit training, with the aim of increasing employee knowledge in Group companies.

As of March 31, 2010, 12 companies belonging to the Group Environmental Committee have acquired ISO14001 certification, and 20 companies are building an EMS that conforms to the ISO14001 standard. TEPCO Group companies keep track of their environmental load targets and achievements, compile environmental activity reports, and disclose them on their respective websites.

Tokyo Electric Power Services Co., Ltd.: www.tepsco.co.jp/index-e.html

TEPCO provides various employee training programs to assure its employees are capable of acting in an environmentally friendly manner at all times during the execution of their duties.

A variety of training programs are available to employees who are assigned to environmental duties, such as Environmental Managers who play a central role in promoting environment management in their respective office, internal environmental auditors and waste management officers. These programs offer specific knowledge appropriate to each employee's experience level.

A broad menu of support services also helps employees enhance environmental awareness and knowledge, such as by sharing information on environmental laws/regulations and their amendments via Intranet, and providing consultation on environmental activities.

Major group environmental training programs (FY2009)

| Name of program | Description | Attendance record*1 |

| Training program for new Environmental Managers and environmental officers | EMS, trends in global warming issues, management of waste materials and hazardous substances, environmental communication, etc. | 139 |

|---|---|---|

| Environmental laws and regulations | Study of major environmental laws, regulations, and manuals, practical knowledge of compliance confirmation methods, etc. | 69 |

| Basic training in internal environmental auditing | Overview of EMS, basic internal auditing procedures, audit simulations, etc. | 66 |

| Workshop on proper waste treatment (for working-level and middle management-level employees) | Study of laws and regulations related to waste materials, practical knowledge of waste treatment methods, etc. | 977*2 |

| Training for development of nature observation guides | Knowledge of nature, safety measures, observation guidance skills, program-making, etc. | 98*2 |

| Qualification acquisition courses | Preparation for the Certification Test for Environmental Specialists (Eco Test) Preparation for the pollution control managers examination (air quality) |

283 |

At TEPCO, we implement general environment education for all employees. Through e-learning programs provided via Intranet, they develop environmental awareness by learning about TEPCO's environmental initiatives, about global environmental issues such as global warming, and about other topics related to the environment.

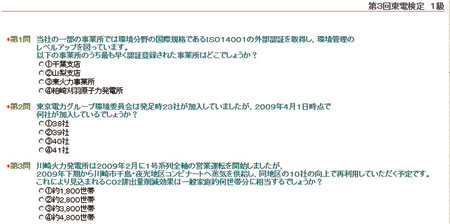

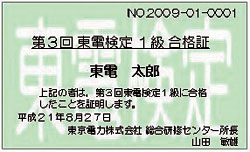

In June-July 2009, more than 10,000 employees participated in the TEPCO Examination (Environment) on the company's environmental initiatives. The examination allowed the participants to diagnose their own knowledge level, as well as inspired further interest in the environment.

At the office level, independent efforts are being made to increase environmental awareness and knowledge among employees, such as by organizing study groups about the content of TEPCO's Sustainability Report, and holding lectures on heat pumps, electric vehicles, and other topics of high social interest.

The TEPCO Examination (Environment) screen and certificate of completion

The TEPCO Examination (Environment) screen and certificate of completion

The TEPCO Group's environmental performance

| Item | TEPCO | TEPCO Group companies*3 | |||||

| FY2007 | FY2008 | FY2008 | FY2007 | FY2008 | FY2009 | ||

| CO2emission*1 | kt-CO2 | 112 | 87 | 83 | 43 | 37 | 35 |

|---|---|---|---|---|---|---|---|

| Electricity used in offices*2 | GWh | 235 | 227 | 223 | 77 | 78 | 76 |

| Water usage | million m3 | 1.34 | 1.28 | 1.23 | 0.44 | 0.42 | 0.39 |

| Vehicle fuel consumption(gasoline consumed per driving distance) | l/km | 0.095 | 0.094 | 0.093 | 0.101 | 0.101 | 0.095 |

| Gasoline consumption | million l | 5.28 | 4.96 | 4.70 | 4.56 | 4.66 | 4.39 |

| Sheets of copy/printer paper purchased (A4 equivalent) | million | 310 | 300 | 320 | 220 | 220 | 230 |

| Industrial waste recycling rate | % | 100 | 99.8 | 99.9 | 91.7 | 90.0 | 91.0 |

| Industrial waste produced | kt | 784 | 750 | 774 | 1,212 | 1,146 | 1,203 |

© Tokyo Electric Power Company Holdings, Inc.