Atmospheric Corrosiveness Evaluation Using ACM Sensors

Background

Quantitative evaluation of atmospheric corrosiveness is an important issue in regards to the maintenance and service life estimation for power generation facilities that are exposed to the atmosphere. TEPCO uses atmospheric corrosion monitors (ACM) to collect corrosion rate data at more than 150 locations in the piping, allowing us to create corrosion rate evaluation maps for galvanization and carbon steel.

Main Results

Corrosion Service Life Examination

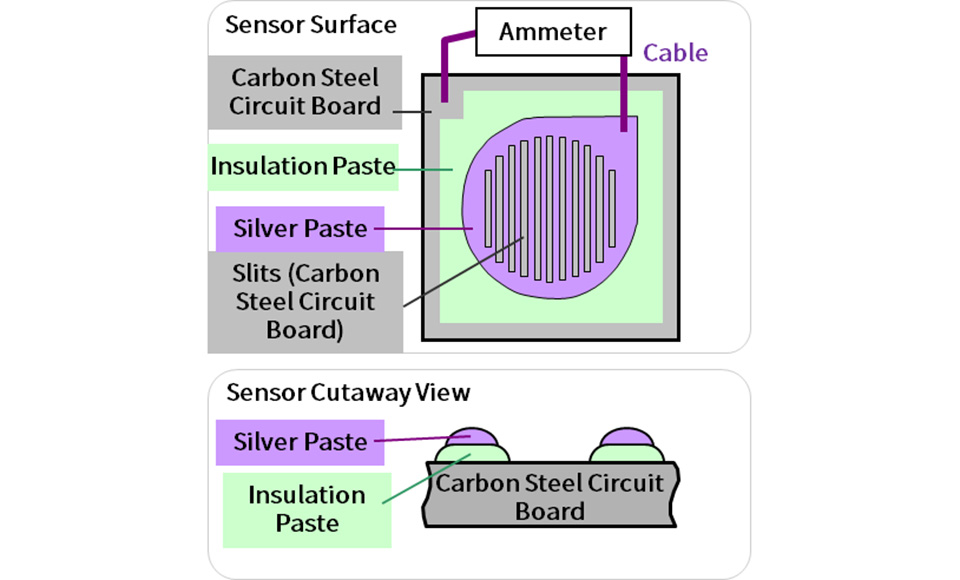

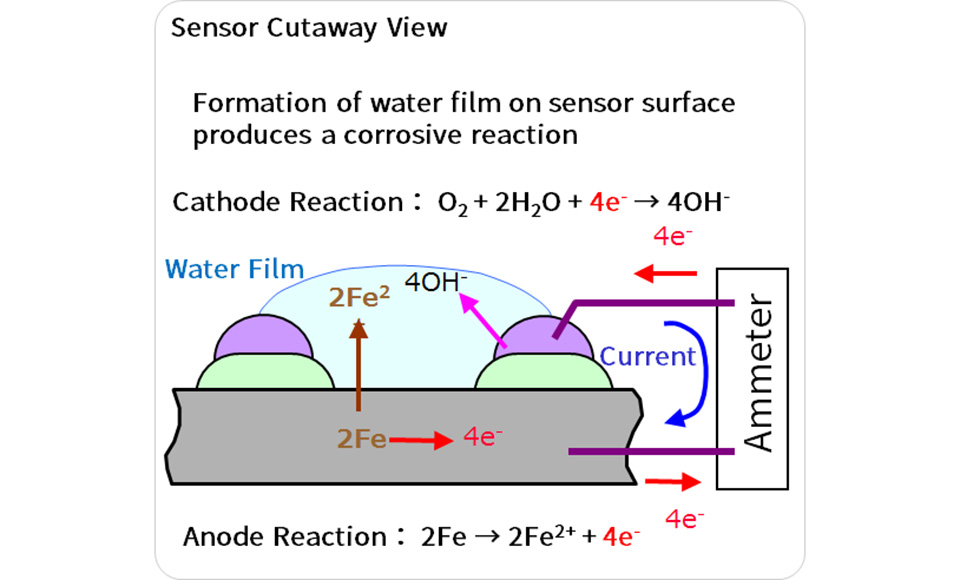

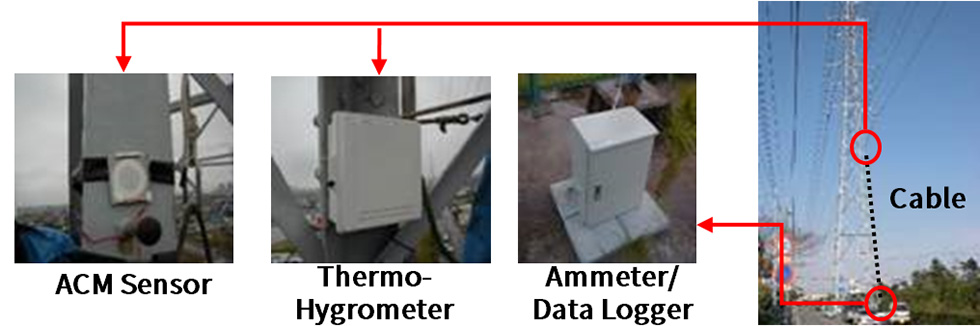

A water film is created on the ACM sensor surface from rain, dew, and adhering foreign material, resulting in corrosion forming on the carbon steel circuit board and the passage of electric current. The size of this current is measured in order to evaluate the corrosiveness of the environment.

ACM Sensor Construction

ACM Sensor Measuring Principles

Example of Tower Installation (1)

Example of Tower Installation (2)

Creating Corrosion Rate Maps

Data measured by ACM sensors (corrosion rate) and the environmental, climatic, and topographic factors that serve as the sources of atmospheric corrosion are used to create corrosion rate maps of carbon steel and galvanization that support the creation of long-term equipment maintenance plans.

Corrosion Rate Map

Applications and Examples of Results

Corrosion evaluation, establishment of corrosion countermeasures, and consulting for equipment using ACM sensors are performed. Training related to corrosion and materials deterioration is carried out, as well as the evaluation of corrosion and damage causes in order to create corrosion rate maps for wide-ranging areas.