The Status of Fuel Debris Retrieval

In Units 1 to 3, the fuel and the metal cladding that forms the outer jacket of the fuel rods melted, then re-solidified as fuel debris. To reduce the risk from this fuel debris, fuel debris retrieval commenced from the first unit (Unit 2), to gradually enlarge the scale of the retrieval. The retrieved fuel debris will be stored in the new storage facility that will be constructed within the site. Details are available here (Fuel Debris Portal Site).

What Is Fuel Debris?

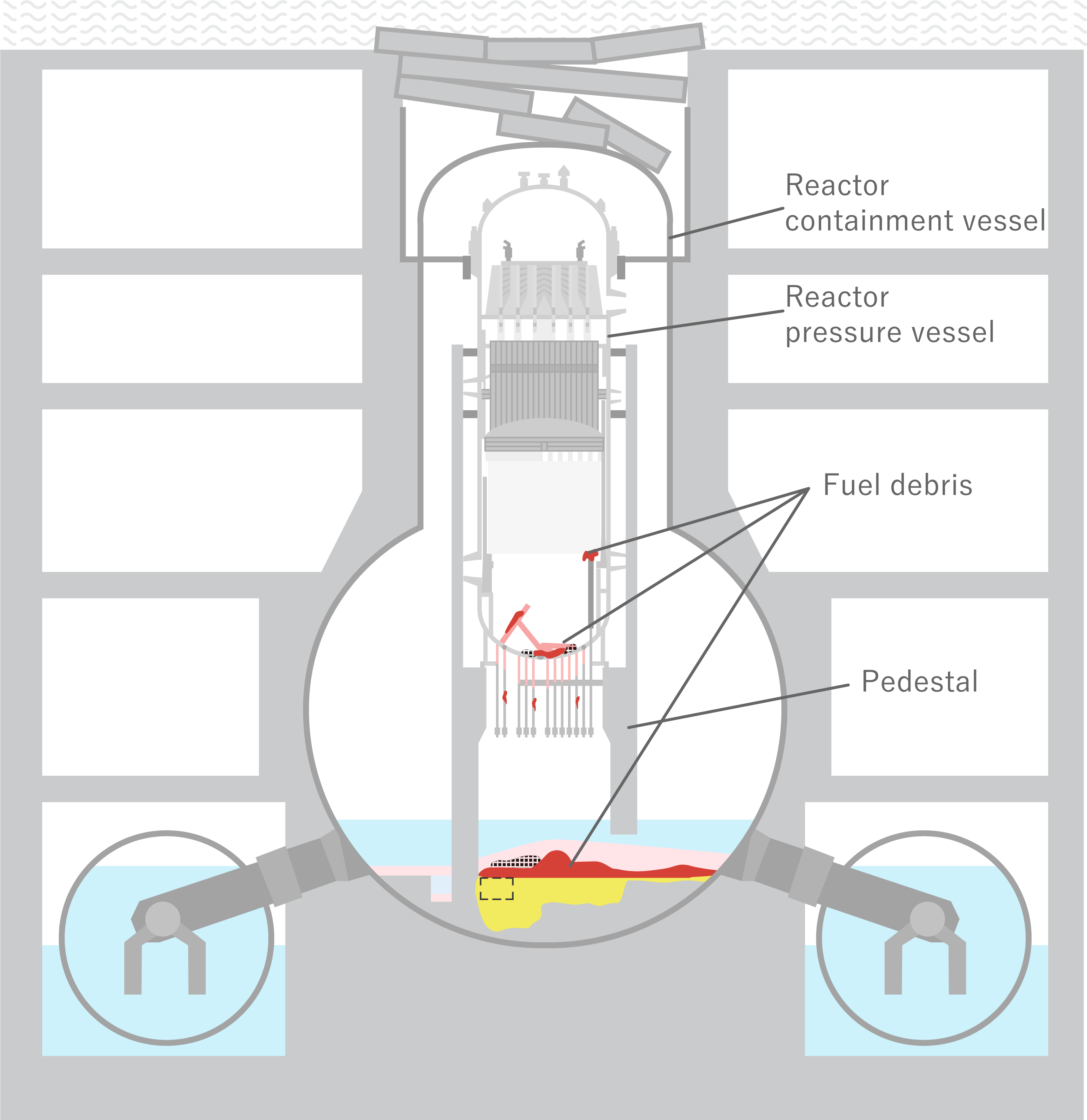

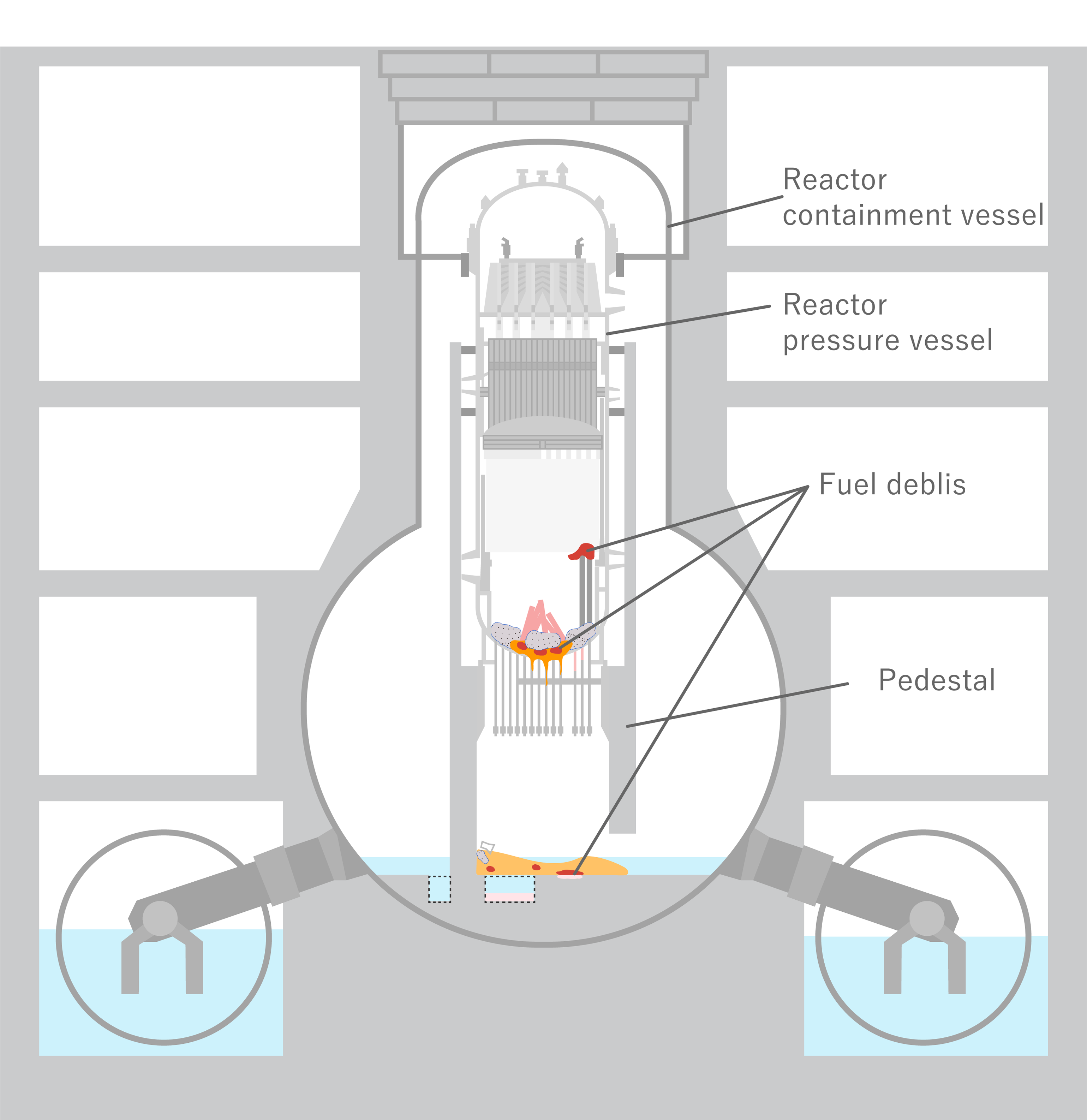

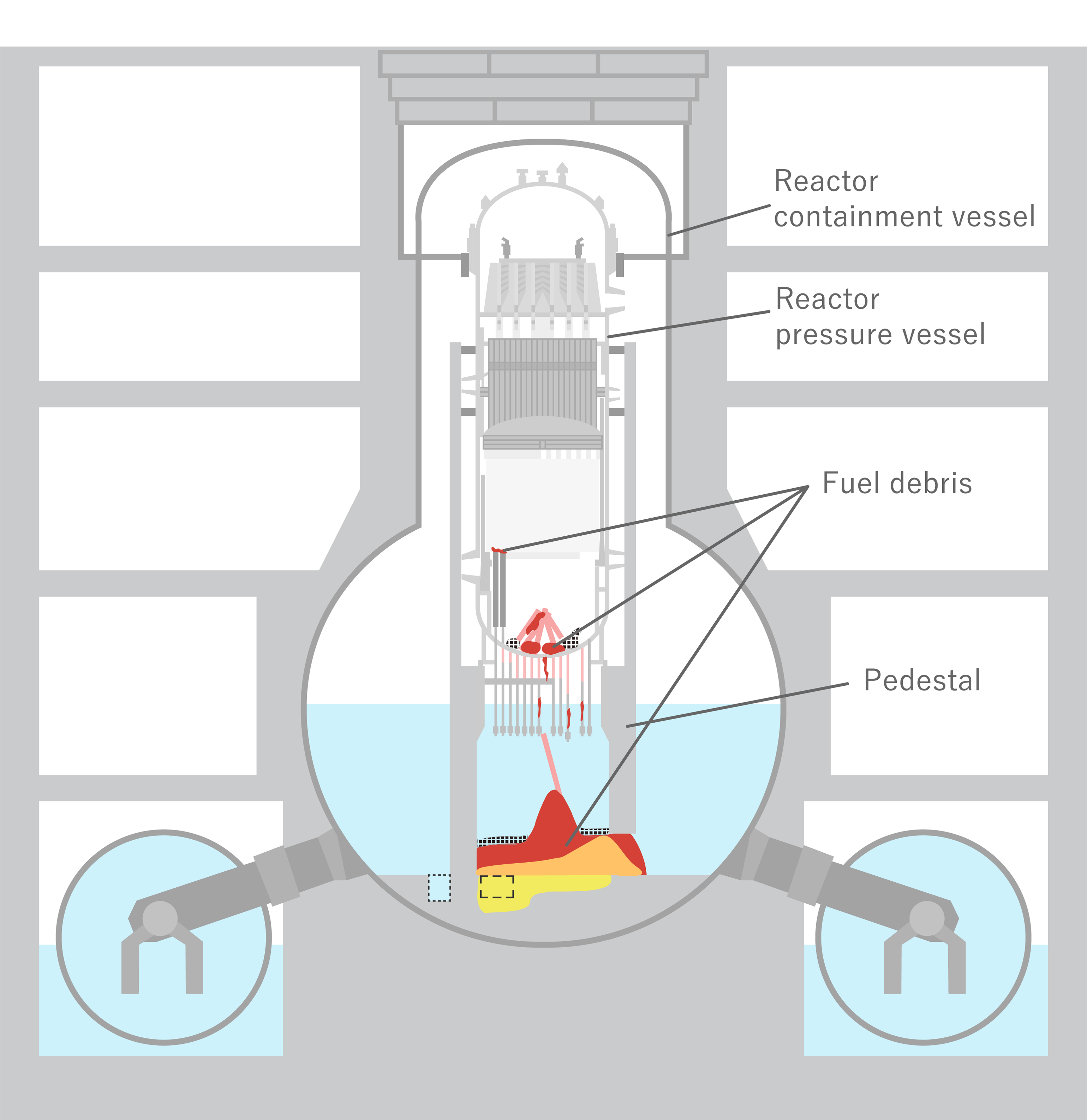

At the time of the accident, Units 1 to 3 were operating and had fuel rods loaded in the reactors. After the accident occurred, the loss of emergency power prevented further cooling of the cores, resulting in overheating and melting of the fuel. Fuel debris refers to this melted fuel and other substances after they cooled and re-solidified.

Estimated Distribution of Core and Containment Vessel Fuel Debris in Each Unit

Approach to Retrieving Fuel Debris

| As the retrieval is being carried out, the approach will be adjusted flexibly based on information obtained gradually over the course of the operation. | |

| A comprehensive plan will be studied, aimed at overall optimization, from the preparatory phase to fuel debris retrieval work, transport, processing, storage, and cleanup. | |

| A combination of engineering methods will be studied, optimal for the location of the fuel debris, built on the basic approach of accessing the bottom of the containment vessel from the side and accessing the pressure vessel from above. |

Fuel Debris Retrieval Steps

Step 1: Surveys inside containment vessels

Surveys using robots and other means will be conducted to obtain information about the state inside the containment vessels.

Efforts of Primary Containment Vessel Internal investigation (chronology)

Step 2: Fuel Debris Retrieval

Fuel debris retrieval will be carried out on an experimental bases and the conditions of the fuel debris will be analyzed. Furthermore, the scale of the fuel debris retrieval will be enlarged based on the obtained information from Primary Containment Vessel internal investigations and experimental retrieval.

Step 3: Storage

The retrieved fuel debris will be transported with the specially designed container to the new storage facility that will be constructed within the site.

Status of Each Unit

Surveys will be conducted in the containment vessels of each unit, to confirm the status of fuel debris and the structures around the debris.

The status of progress on the mid- to long-term roadmap (decommissioning and contaminated water measures team meetings/secretariat conferences) is updated in monthly progress reports and other materials.

See the “Fuel debris retrieval preparation” materials here for details.

Related Content

Efforts of Primary Containment Vessel Internal investigation (chronology)

| Unit1 | Unit2 | Unit3 | |

|---|---|---|---|

| 2012 |

October (1st) |

January (1st) March (2nd) |

|

| 2013 |

August (3rd) |

||

| 2014 | |||

| 2015 |

April (2nd) |

October (1st) |

|

| 2016 | |||

| 2017 |

March (3rd) |

January to February (4th) |

July (2nd) |

| 2018 |

January (5th) |

||

| 2019 |

February (6th) |

||

| 2020 | |||

| 2021 | |||

| 2022 | February~ (4th) |